Size of Facility

Program Value

Construction Value

In an effort to reduce environmental impacts associated with the treatment of wastewater, and to recover unused renewable energy at the wastewater treatment plant (WWTP), the City of San Mateo (City) contacted KJ to discuss alternatives.

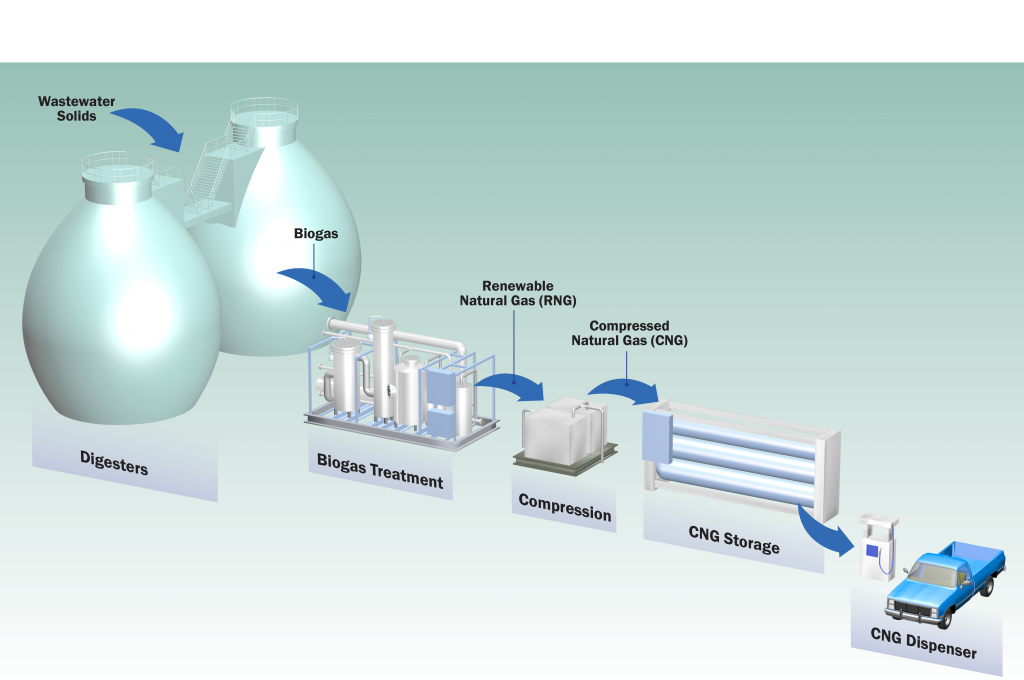

KJ suggested that the City consider using their digester gas (biogas) for vehicle fueling rather than co-generation. We informed the City that a new vendor package to clean biogas to natural gas quality is now commercially available for the volumes of biogas typically produced by mid-sized WWTPs. Further, based on a similar analysis KJ had just completed for the City of Roseville, producing vehicle fuel was the most cost-effective alternative for beneficially using biogas. City staff were very interested in this alternative and retained KJ to analyze whether producing vehicle fuel from biogas would be feasible and cost-effective. The analysis completed by KJ indicated that the City could produce approximately 500 gas gallon equivalents per day of compressed natural gas of vehicle fuel from their biogas with a simple payback period of approximately 8 years. This payback period is significantly less than the simple payback typically realized by cogeneration projects using biogas, which is a more commonly used energy recovery approach.

Subsequent to KJ’s completion of the analysis for the City, the California Energy Commission solicited competitive proposals for grant funding of projects to produce biomethane for vehicle fuel. The City decided to submit a grant application for its project and retained KJ to assist with the production of the grant application. The City’s grant application was successful and the California Energy Commission awarded a grant to the City which will pay for approximately 50% of the total project cost.

Upon garnering the grant from the California Energy Commission, the City decided to proceed with the project and retained KJ to provide predesign, design, bidding, and engineering services during construction for the project.

Waste gas burner for off-gas and biogas

The gas treatment system produces an off-gas that contains carbon dioxide and methane that has a low BTU content and could not be combusted by the existing waste gas burner. Consequently, a new waste gas burner was needed to combust the off-gas. Further, the existing waste gas burner needed to be moved to allow the installation of the gas storage system, so it could no longer be used to combust the waste biogas. Based on all this, KJ designed piping and control modifications so that the new waste gas burner could combust both the off-gas and the waste biogas, which was a new approach for handling these waste gas streams at a WWTP.

Furthermore, KJ needed to develop a control strategy that would control the biogas flow to the multiple biogas uses while avoiding the inadvertent release of any biogas to atmosphere. In addition, the control strategy needed to prioritize the delivery of the biogas to the production of vehicle fuel, which has the highest economic value for reuse of the biogas. The plant was using an existing variable pressure-constant volume gas control system that KJ concluded would not be able to control the biogas flow to meet the above criteria. As a result, KJ designed a constant pressure-variable volume gas control system using a low pressure gas storage system to control and prioritize the biogas flow. The prioritization to distribute the biogas was based on biogas storage volume in the gas storage system.

Site Constraints

The wastewater treatment plant site was very small with very little available land to install the new facilities. In addition, the facilities were installed adjacent to biogas and CNG equipment, and the electrical components had to be installed to meet electrical code clearances. Consequently, with these many constraints, siting the equipment proved very challenging. The facilities were not adjacent to one another so piping had to be routed across the site to interconnect the facilities. Because of the large distance, hard wiring for electrical controls between the gas treatment and vehicle fuel controllers was not possible. Instead, KJ developed a control strategy to use Ethernet communications by connecting to the plant’s programmable logic controller network.

Extraordinary Permitting Circumstance

The project needed to be permitted by the local air quality district, and since the gas treatment equipment, the waste gas burner, and the vehicle fueling equipment had not been installed together at a WWTP, the air quality district staff had difficulty determining how to permit the equipment. KJ spent a significant amount of time with the air quality staff describing the operation and performance of the equipment, and explaining how the equipment worked together, and that the project would reduce air emissions. Ultimately, KJ was able to explain the project sufficiently and the air quality district permitted the project.

Exceeding Client/Owner Needs

The development of the Digester Biogas to Clean Burning Vehicle Fuel project was considered a successful collaboration between the City and KJ. Regular teaming sessions and stakeholder workshops were held throughout the design period to provide an opportunity for collaboration and discussion resulting in a streamlined schedule. The project was considered a cost-effective solution, due to procurement of the $2.45 million grant from the California Energy Commission, and the cost analysis indicating that simple payback would occur over a period of approximately eight years. Design fees did not exceed budget, and the project was completed on time. The City is proud to be at the forefront of this emerging technology to achieve their Climate Action Plan and sustainability goals by switching from petroleum fuel to renewable, clean burning vehicle fuel produced from biogas.